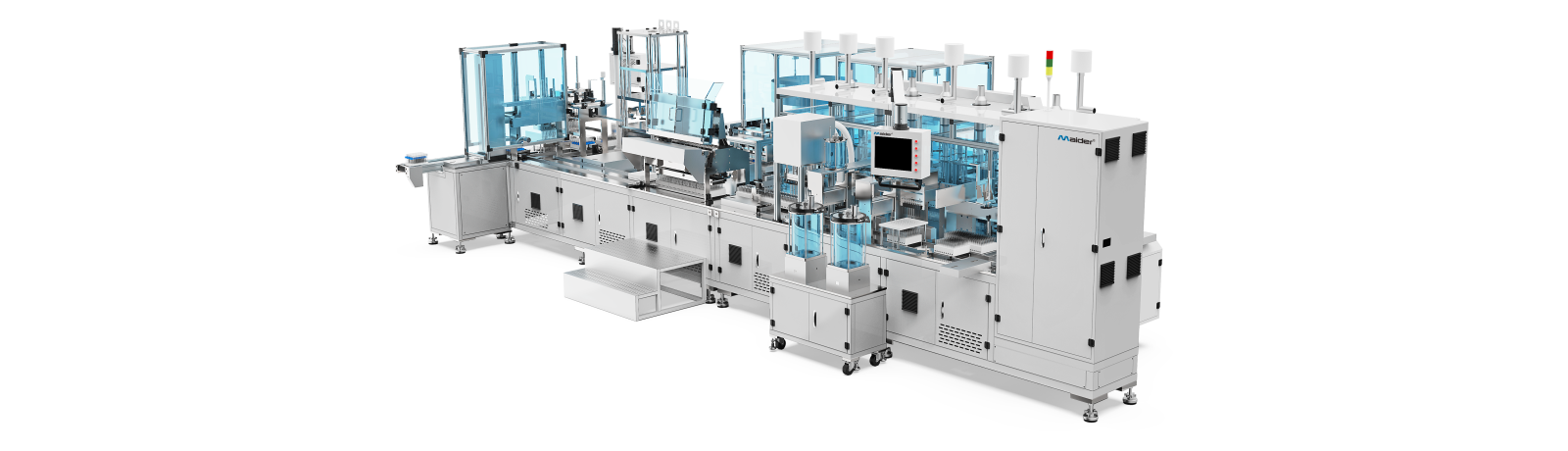

Vacuum blood collection tubes, fully-enclosed systems for blood sample collection, significantly improve the quality of blood samples and enhance laboratory quality control before analysis. Compared with the traditional blood sample collection by syringes, these vacuum tubes will further ensure the safety of healthcare professionals and avoid bloodborne cross infection. However, it is difficult to realize its automatic assembly due to technical difficulties such as vacuuming and additive spraying.Against this bottleneck in the industry, Maider has independently developed an automatic assembly line for vacuum blood collection tube, an industry-leading intelligent manufacturing system for medical consumables. Deviating from traditional manufacturing that relies on manual assembly, this system realizes an all-in-one automatic system involving material loading, detection, additive spraying, assembly, packing, and material unloading. This highly-automatic and complete process leads to the efficient and reliable manufacturing of vacuum blood collection tubes, marking a breakthrough in the automatic assembly of vacuum blood collection tubes by Chinese enterprises and helping large-scale medical enterprises achieve digitalized manufacturing, which minimizes their order delivery time and production costs.